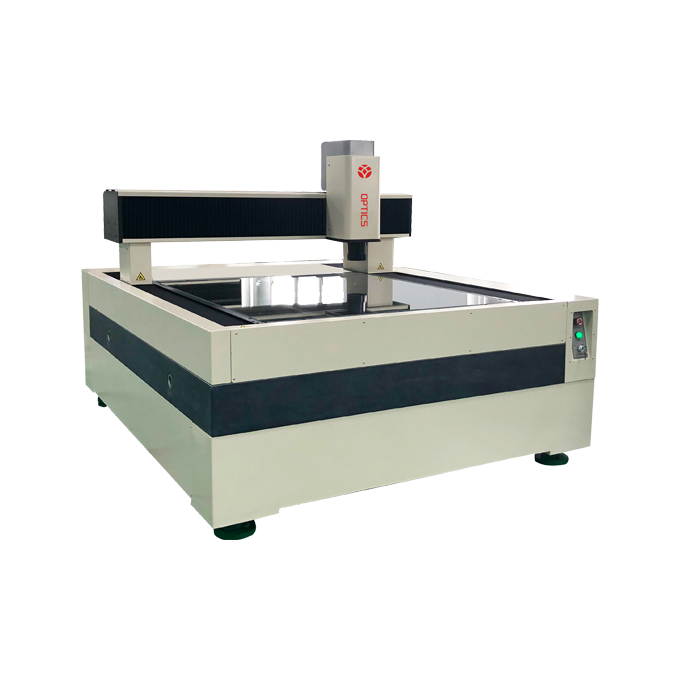

| Precision Equipment Hardware: |

| 1 | Marble base, post and worktable, stable, firm framework. |

| 2 | Marble table. Reducing mechanical assembly error, ensure precision movement of X, Y axes. |

| 3 | High verticality of X, Y axes can ensure measurement accuracy up to 2.5+L/ 200um. To get high precision even without coordinate detection function. |

| 5 | Precision Ballscrew transmission make movement fast, flexible and reliable. |

| 6 | Optical grinded Glass working stage, Z-axis is calibrated to ensure travel direction vertical to glass plane so that the measuring result with high accuracy. |

| 7 | Programmable laser pen positioning allowed the machine find appropriate position rapidly and work more quick. |

| 8 | The first one who introduced sub-pixel measurement in video measure industry. Do not need any professionaloperation skills for operator, enhance measuring efficiency greatly. |

| 9 | Automatic Z axis focusing enhanced the precision while refocusing, user need to move X, Y axes only, convenient and quick. |

| Smart Software Software |

| 1 | Multiform output such as DXF,WORD, EXCEL etc. CAD drawing input and comparison function. It can directly measure and calculate straightness, roundness, position, parallelism, inclination, perpendicularity, concentricity, symmetry, and other geometric tolerances. |

| 2 | Ample geometrical measurement function including drawing, label, edit, operation board measure etc., It provides measurement and drawing functions for point, line, circle, arc, ellipse, groove, rectangle, closed curve etc. |

| 3 | SPC key parameters analysis according to the data of report form, automatic calculation of Ca, Cp, Cpk, Max, Min, Range, Avg, Std etc. |

| 4 | Auto tolerance output and alarm with color, sound and note, especially have product dimension tracking function. |

| 5 | LED three ring lights on octant top(eight segment) + transparent parallel lights, brightness adjustable |

| 6 | Fast & automatically focus function. One focusing in one second. Repeatability of focusing at high magnification is<0.01mm, If the focusing time is set to 2 to 3 seconds. |

| 7 | Can measure the various complex graphics including curves. |

| 8 | Powerful photograph, montage and virtual measuring function. |

| 9 | Lasers and probes can be added if needed, so as to complete the three-dimensional size measurement. |

| Ultra-fast Detection Detection Efficiency |

| 1 | Testing product: ≤500*400*200mm, suitable for various of production’s inspection |

| 2 | Fast procession to single product or feature detection |

| 3 | Fast moving speed of worktable: the fastest moving speed of XY axis is 200mm/s, acceleration can reach 400 |

| 4 | Fast image calculation speed: powerful image calculation processing and calculation capabilities, work does not need to be corrected, coordinate conversion function, high measurement efficiency |

| Stable Performance Operations: |

| 1 | Continuous operation, low failure rate, normal basic maintenance once every 6 months |

| 2 | Continuous operation with high utilization rate: 7*20H |

| 3 | Long service life: Imported high-precision component modules are selected to ensure the long-term stability of the equipment |

| 4 | Good repeatability: the accuracy of the equipment remains unchanged after long-term operation |